Roller conveyor is composed of the most components, is the smooth operation of the conveyor is one of the main factors; its service life on the conveyor operating costs. After years of continuous improvement, our company has gradually formed its own unique and efficient, reliable production process. The production roller adopts the special-purpose steel tube of high-precision roller, the high-precision end face flange bearing seat, the steel pipe exempts the processing mouth technology; Uses the new seal, has the precision to be high,

order

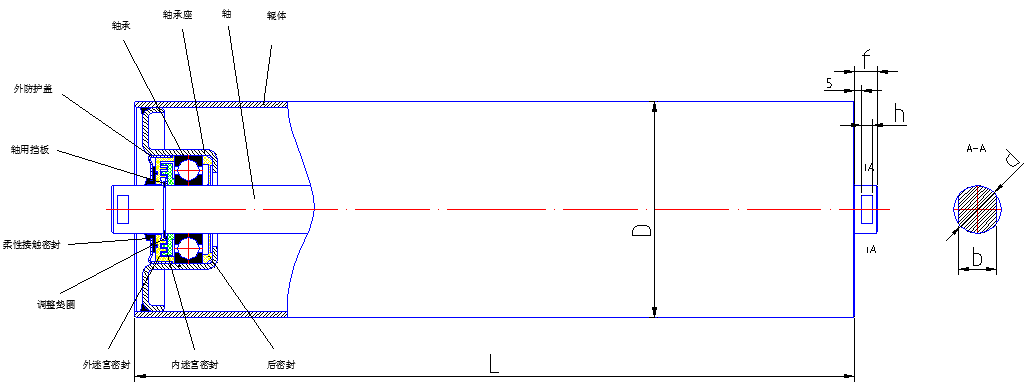

AH idler roller Introduction:

AH roller is my company's patented product

Roller conveyor is composed of the most components, is the smooth operation of the conveyor is one of the main factors; its service life on the conveyor operating costs. After years of continuous improvement, our company has gradually formed its own unique and efficient, reliable production process. The production roller adopts high-precision special-purpose steel tube for roller, high-precision end face flange bearing, steel pipe free-machining process. It adopts new type sealing, which has the advantages of high precision and long service life. The sealing characteristics are as follows:

1. A flexible contact seal is provided at the position of the roller shaft between the two rotors to ensure that the foreign matter can not enter the bearing chamber and the idler chamber. This position is the minimum contact area of the two rotors, so the rotation resistance is relatively small.

2, the outer protective cover can be a good seal and control to protect the flexible seal, sealed by external impact damage is not easy.

3, shaft spring retaining ring placed inside and outside the labyrinth seal between the internal and external seal control, will not have internal and external seal friction risk. Spring retaining ring from the bearing position closer to the axial force of the roller bearing capacity, so the roller has a good axial impact resistance.

Quality commitment: I produced the AH series roller warranty for one year, under normal working conditions, the use of 50000h damage rate of not more than 10%.

I produced the roller is better than MT821-2006 "coal conveyor with roller technical conditions", GB10595-89 "belt conveyor technical conditions" standard.

Company's products manufacturing standards:

1, roller roller (in addition to the buffer, comb-shaped and other special roller outside) circular radial round beating

Roll length

Idler Length / mm

? 550

≥ 550 to 950

> 950 to 1600

> 1600 to 2400

0.4

0.5

1.0

1.2

2, roller roller assembly, the 500N axial pressure, the axial displacement of the roll should not be greater than 0.4mm.

3, roller roller assembly, the radial pressure in 250N, the roller to 600r / min rotation, measured the rotation resistance, its value should not be greater than the values in the following table. After 1 h of rotation, the rotational resistance shall not exceed 1.5 times the value in the following table.

Contact: Manager Liu

Tel: 0317-5128131/5128282

Mobile: 13483852999

E-mail: [email protected]

Address: Cangzhou City, Hebei Province, Yanshan County, East outer ring